Sample Applications /

Hardware Overview

Sample Application 1

Sample Application 1

A cereal

manufacturer is producing a new breakfast product for their market. They request from IACD a temperature control

package for the process. This will

require the monitoring of 75 RTD’s with 15 active PID control loops varying

steam and cooling water systems for temperature control. These loops are then network connected to a

control room Human Machine Interface (HMI) package for process supervisory

features to include recipe management and data acquisition.

Sample

Application 2

A

pharmaceutical company requests from IACD a design for a wash control system to

sterilize vials prior to filling on a high speed bottling line. System will be required to monitor

temperature, pressure, and speed of the line.

Then based upon these readings control the temperature and the pressure

to guarantee sterilization based upon rate of the line. The faster the movement of the line the

higher the temperature and pressure must be to guarantee sterility of the

vials. System must be designed with

both automatic and manual modes of operation as well as monitoring alarm

signals from the other process stages.

Sample Application 3

Sample Application 3

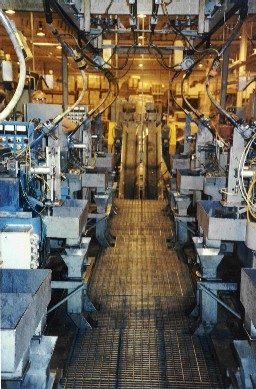

A metal

foundry requests from IACD a control system for their tempering furnaces. System must control conveyor rates, and 12

temperature control zones in the process to assure gradual increase and

decrease of product temperature during production. System will require the development of an Operator Interface as

well as an audible safety alarm system on the furnace gas supplies.

(Note:

The previous three examples are all based upon actual projects that have

already been implemented by the talented personnel here at IACD.)

SampleHardware

Overview

|

Allen Bradley PLC2/3/5,SLC 100/150/500, Mitsubishi Delta

V Modicon GE

Fanuc Siemens

/ TI (S5 / S7) |

Sensors

and Controllers Sunex Watlow General

Electric Accusort PSC |

Modbus TCP Modbus RTU Modbus Plus Ethernet

I/P DH1 DH485 RS232 DNP.3.0 Device Net Profibus DP Profibus PA Foundation

Fieldbus Foxcom HART |

|

PC

Operating Systems & Software MS Windows 3.X/95/98/Me/NT/2000/XP UNIX Visual

Basic C

/C++ Basic Fortran Pascal COBOL Auto

Cad Micro-Station Miscellaneous

. Other |

Operator

Interfaces (HMI /MMI) Intellusion Labview Factory

Link Data Bases / Sequel Servers |

HMS

SST Data Linc Group Radios and Line Modems Elpro

Technologies Radios and Telemetry Systems N-Tron Ethernet Switches and Fiber Optic Converters Emerson

Servo Control Reliance

Automax Control Systems General

Electric

Robotics Hitachi

Robotic Systems |

|

|

|

Home | Services | Applications

| Press

| Techsheets

| Contact |

RKICorp |